MIL-W-25038 Wire

These wires are designed for critical circuit applications where wires must operate in extremely harsh environments, under vibration, and with direct flame exposure.

| Requirements | Results | |

|---|---|---|

| MIL-W-25038 | 50 Ω | 10 kΩ |

| MIL-W-25038/1 Construction Details | |

| Jacket | PTFE-coated fiberglass braid and finisher |

|---|---|

| Insulation | Composite inorganic dielectric |

| Conductor | 27% nickel-coated copper ranging from 22 – 4/0 AWG |

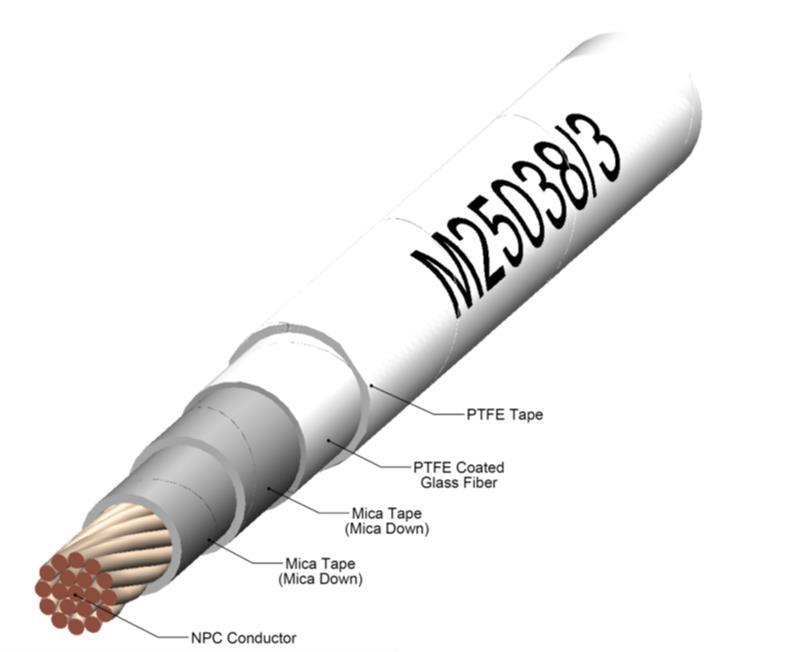

| MIL-W-25038/3 Construction Details | |

| Jacket | Fused high-performance PTFE tape (also available with Seamless Wrap PTFE tape) |

|---|---|

| Insulation | |

| Thermazone IIIK | Outer: PTFE/polyimide tape fluid barrier

Inner: Inorganic dielectric |

| Thermazone IIIG | Outer: PTFE-coated fiberglass fluid barrier

Inner: Inorganic dielectric |

| Conductor | 12-18 AWG: 27% nickel-coated copper

20-22 AWG: 27% nickel-coated high-strength copper alloy |

| Voltage Rating | 600 V |

| Temperature Rating | -55 to 260 °C |

| AWG | 22-12 |

MIL-W-25038/1 & MIL-W-25038/3 datasheet (Thermax)

Thermazone™ Cables datasheet

To inquire about MIL-W-25038 Wire available from CarlisleIT, please fill out the form below, and one of our Sales Engineers will contact you.

"*" indicates required fields