BMS 13-55

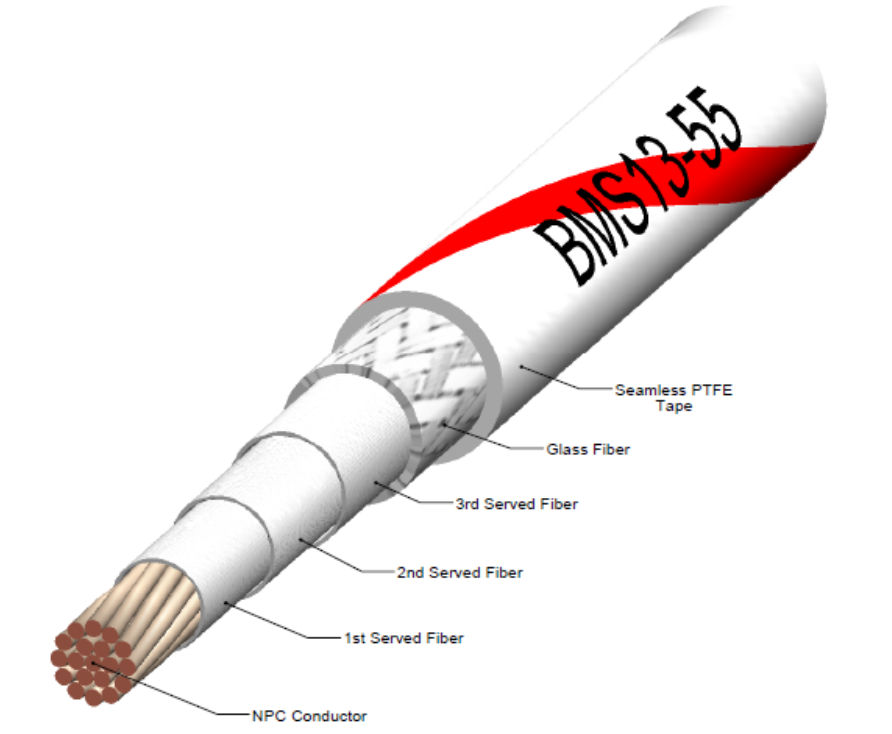

BMS 13-55 is the Boeing specification for Firezone wire. These wires are designed for critical circuit applications where wires must operate in extremely harsh environments, under vibration, and with direct flame exposure.

| Requirements | Results | |

|---|---|---|

| BMS 13-55 | 10kΩ | 500kΩ |

| Conductor | Nickel-plated copper |

|---|---|

| Insulation | Impregnated inorganic fiber and TFE coated glass braid |

| Jacket | Seamless-wrap PTFE tape |

| Identification | Surface printed per BMS 13-55 |

| Colors | Color coated per BMS 13-55 |

| Voltage Rating | 600V |

| Temperature Rating | -65 to 260°C |

| Boeing P/N | P/N | AWG | Stranding | Nominal Conductor Diameter | Nominal Insulation Diameter | Weight lbs/1000ft (kg/1000M) | Maximum Resistance |

|---|---|---|---|---|---|---|---|

| BMS13-55T01 C01 G12 | 12-BF1-1925 | 12 | 19/25 | 0.088(2.24) | 0.157(3.99) | 29.11(19.5) | 2.78(9.12) |

| BMS13-55T01 C01 G14 | 14-BF1-1927 | 14 | 19/27 | 0.07(1.78) | 0.123(3.12) | 18.25 (12.3) | 4.32 (14.2) |

| BMS13-55T01 C01 G16 | 16-BF1-1929 | 16 | 19/29 | 0.055(1.39) | 0.108(2.74) | 12.71(8.5) | 6.86 (22.5) |

| BMS13-55T01 C01 G18 | 18-BF1-1930 | 18 | 19/30 | 0.049(1.24) | 0.101(2.57) | 10.53(7.1) | 9.14(30.0) |

| BMS13-55T01 C01 G20 | 20-BF1-1932 | 20 | 19/32 | 0.039(.991) | 0.093(2.36) | 8.01(5.4) | 14.57(47.9) |

| BMS13-55T01 C01 G22 | 22-BF1-1934 | 22 | 19/34 | 0.031(.787) | 0.086(2.18) | 6.35(4.3) | 23.7(77.7) |

Thermazone™ Cables product information sheet

To inquire about BMS 13-55 Firezone Wire available from CarlisleIT, please fill out the form below, and one of our Sales Engineers will contact you.

"*" indicates required fields